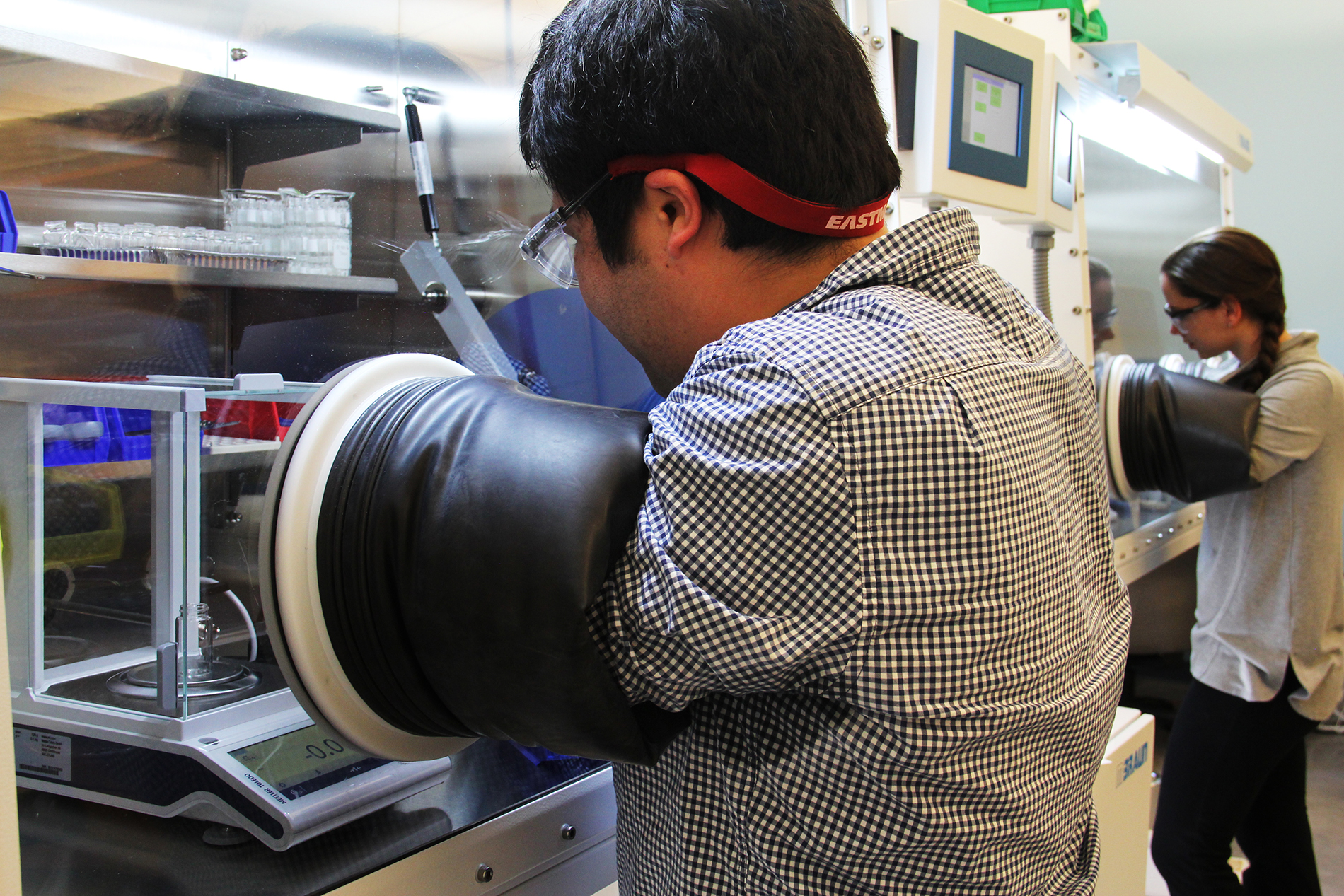

Javier Grajeda, a PhD student in the UNC Department of Chemistry, dons a pair of safety goggles attached to a red strap that reads “Eastman.” He inserts his hands into a set of black, rubber, superhero-sized gloves. His nimble fingers weigh a series of powdered metals on a scale within the square, airtight space he’s working in — an inert atmosphere glove box, which prevents contamination.

After placing the powders into 18 individual vials, he passes them through an antechamber and into another box on the right, where his labmate, Chrissy Roselli, takes them off his hands. She adds a liquid solvent to dissolve the powder in each vial and places them back in the antechamber. Then, she slips her hands from the gloves, removes the vials from the biodome-like contraption, and heads to the other side of the lab, where she and Grajeda load all 18 solutions into a reactor that pressurizes them.

What are they searching for? New catalysts that will speed up the production process for chemicals used within multiple industries, from agriculture to textiles to pharmaceuticals. The study of catalytic reactions has led to the development of chemical processes such as large-scale production of ammonia — used worldwide to fertilize crops — and to the invention of catalytic converters, which prevent cars from emitting dangerous amounts of carbon monoxide into the atmosphere.

The catalysis lab at UNC exists thanks, in part, due to industry funding from Eastman, a global advanced materials and specialty additives company headquartered in Kingsport, Tennessee. The company has developed a variety of products from catalysts such as Eastman Tritan™ copolyester, one of the first BPA-free durable plastics on the market.

Grajeda and Roselli use inert atmosphere glove boxes to keep the chemical environment sterile for experimentation.

UNC’s research relationship with Eastman goes back to 2012, when the company began searching for a university partner to establish a Center of Excellence. They visited more than 50 colleges across the nation before settling on both Carolina and NC State.

Today, Eastman has ongoing projects not only within the Department of Chemistry but also Applied Physical Sciences and Physics and Astronomy, as well as the UNC Gillings School of Global Public Health and the Kenan-Flagler Business School. While they were slated to invest $1.5 million over six years, they’ve already given more than $3.5 million to Carolina for nearly 20 projects — and this is only year five.

“I think UNC provides cutting-edge research and technologies that other universities may not have,” Joonhyung Cho, the relationship manager for Eastman, says. “We also have a good reputation in the areas of chemistry and materials science — something Eastman is interested in.”

Most industry-funded academic research occurs with a narrow scope. UNC chemist Alex Miller recalls his time as graduate student, when he worked on a team collaborating with another company. “A lot of industry chemical partnerships that I’ve seen in the past are really targeted at a single investigator or a small group of people focused on one problem,” he says.

But Eastman’s approach is innovative.

“Eastman is really flexible and has a diversity of problems and is working with researchers within different departments across UNC,” Miller says. “It’s this dynamic, functional research effort that shifts with changing interests on both sides — and that’s a really great model.”

Listening intently

In November 2012, Eastman visited UNC to host a brainstorming session on the science they were interested in and their ongoing projects. Fellow Joe Zoeller (now retired) presented slides on an internal project involving the synthesis of acetic acid — one of the processes Eastman is known for.

Miller approached Zoeller to share some of his early UNC research, and the two scientists realized they were both working on projects using similar metal elements. “Over a cup of coffee, we hashed out some research ideas and were really excited about what the other had done in prior research,” Miller says. “We kept talking after that day and eventually Eastman funded one of my projects — a big deal for me because I was only a second-year faculty member. It launched my research program, which is still going strong.”

Since then, Eastman scientists have worked with Miller on a total of three research projects and even collaborated on an academic paper with him.

“Eastman is pretty transparent and willing to listen to what we do,” Cho says. “That sounds so simple, but it’s not. We don’t do development. They don’t do research. We don’t speak the same language. For most people, when things aren’t going well, they go back to where they’re comfortable and don’t try to solve the problem — because the problem can’t be agreed upon. But Eastman is always willing to listen one more time. And that allows us to bend a little further to discuss and resolve those issues.”

This is a big deal not only for early- to mid-career researchers like Miller, but for all levels of scientists at UNC. A few years ago, Department of Chemistry Chair Jeff Johnson pitched a “wacky” solution to Eastman for an industrial process they were struggling with. Although both sides decided his idea wouldn’t be a fruitful path forward, the company was extremely receptive to Johnson’s outside-the-box approach.

“You can have a view of business and industry as being very conservative and straight-laced, but one of the things I appreciate about being in academia is being able to think wildly about research problems,” Johnson says. “And to have a company like Eastman respond to that thought-process with that sense of, Wow. That’s a really cool thing we hadn’t thought of. Tell us more. That’s a great interaction.”

Showing up

Four Eastman representatives live in the Triangle, two of whom — Barclay Satterfield and Dawn Mason — share an office at UNC, where they meet face-to-face with researchers and students each week. “We want boots on the ground, we want people here. Because without that you can’t build this type of relationship and maintain it,” Mason, external innovation manager, says.

The company also provides financial support to recruit the next generation of scientists — like when the chemistry department hosts prospective students or brings global leaders in the field to campus for lectures.

They also work one-on-one with PhD students, offering career advice, job coaching, and answering questions about what it’s like to work for a company like Eastman. “Recruiting and hiring has definitely increased with our interaction with students,” Mason says. “We get a really good look at the talent coming out of the labs.”

What began as a collaborative chemistry and materials science research partnership in 2013 has extended into the entire university community. Eastman now has projects within the Department of Environmental Sciences and Engineering in the UNC Gillings School of Global Public Health, three departments within the College of Arts & Sciences, and the Kenan-Flagler Business School.

The company has also joined forces with UNC’s BeAM (Be A Maker) makerspace program. There are four makerspaces on campus — located within the Kenan Science Library, Murray Hall, Haynes Art Center, and Carmichael Hall — and Eastman helps with the cost of the filament, or “plastic string,” that feeds through the 40 3-D printers located in those spaces.

“From a research standpoint, we realize the world is changing and that 3-D printing or additive manufacturing is going to be very important,” says Steve Wright, an Eastman technology fellow and UNC Department of Chemistry alumnus. “We’re not sure how yet, but we want to be prepared for it, so we’re doing materials research to support those types of needs. That’s why it’s important to have this capability at UNC — to achieve those goals.”

These plastic spadefoot toads were created by biology PhD student Catherine Chen, with help from the UNC makerspace team, to aid her research on their mating habits.

Beyond supplying the filament for the 3-D printers, Eastman also provides hands-on training workshops for using them. This past December, the materials company hosted its first of many seminars on 3-D printing technology advancement at UNC. “Our partnership with Eastman gives us access to materials and expertise that we wouldn’t have otherwise,” says Glenn Walters, technical adviser for the makerspaces and research associate within the UNC Gillings School of Global Public Health.

“They have really prioritized research, and they value the importance of pursuing things just because they seem interesting,” he continues. “That’s important in a makerspace — you don’t always have to have a good reason to start doing something. And their support of what we do allows us to bounce crazy ideas off them.”

This effort is supported by Eastman’s philanthropic arm, the Eastman Foundation, which invests in initiatives and programs that focus on education, environment, empowerment, and economic development. “This partnership and makerspace is a great example of opportunities to simulate real-world situations,” says CeeGee McCord, director of the Eastman Foundation and Global Public Affairs. “It helps students develop interdisciplinary skills and gain hands-on experience in an academic environment.”

Planning for more

With only one year left of the original agreement, UNC and Eastman are discussing how to keep the partnership moving forward. “We would like to work with the company to make even more connections with a broad set of faculty members and projects that might even include the business school faculty,” Cho says. “A collaboration between business and science — I think that would add something unique to the world of interdisciplinary research.”

Grajeda and Roselli (the two chemistry PhD students mentioned above), on the other hand, are getting ready to don their PhD hoods — and then head straight for Kingsport to start their new jobs with Eastman. Roselli points to this collaboration as a positive sign of the company’s work culture. “And I like that I’ll be working on projects that will directly impact the world,” Grajeda adds, “such as developing cleaner, more environmentally friendly processes.”

Collaborating with Eastman to improve the safety culture at UNC is Miller’s next focus. “It’s been a big topic of discussion in chemistry about the different approaches to safety in an industrial setting versus an academic lab,” he says. “I think we have a unique opportunity to talk about that with our friends at Eastman, and to bring some of the safety protocols they have there into the labs at UNC.”

No matter the project, partnerships like the one UNC has with Eastman show students the work they do here is relevant in the real world. And it demonstrates UNC’s flexibility with industry partners, in general.

“And it shows researchers the possibilities,” Cho says. “We’re not just doing a company’s product development. We’re publishing papers. We’re doing fundamental science. And I think that’s very important.”